- #Atlas lathe machine how to#

- #Atlas lathe machine manuals#

- #Atlas lathe machine manual#

- #Atlas lathe machine professional#

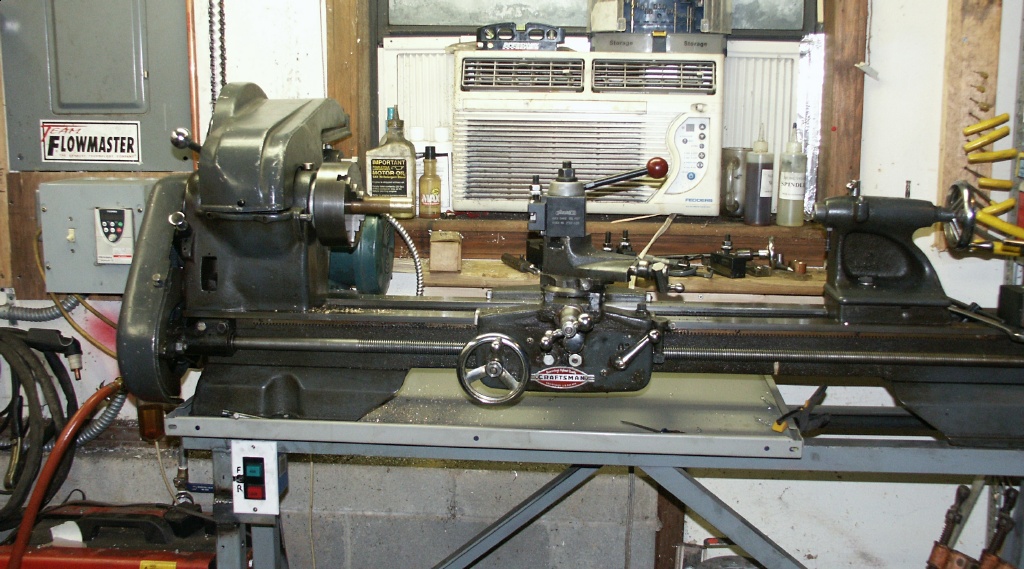

In like the idea of that heavy stand but would say that from the picture it looks to be mounted too far back from the operator. I know that's kind of a broad topic post, but any input or explanation on why the Atlas seems to have such a bad wrap (and ways of fixing it) would be welcome. If I can do that while building a stand, more the better! I'm not looking to turn out high precision work with the old atlas, but I would like to get the most out of it that I can. Would be a while before it happens anyways, the budget can only take so much stretching and I'm buying a new welder this month also (Millermatic 211). I'm not doing production stuff so ease and speed of changing tools is not a high priority, but would probably be a welcome addition in the convenience dept.

I was also thinking of eventually changing out the "lantern" tool holder for a QCTP, but am unsure if that wold do anything for accuracy or not. I'd probably be tossing it even if it did. The guy I'm buying it from has it mounted on a rather nasty looking 2x4 and plywood arrangement and I don't think it even comes with the lathe. I will have to build a stand for my atlas either way. I like the ease of access to the chip tray, I like the added space under the hand wheels, I like the way it manages dripping oil (or coolant if I ever build that) and if it actually does add a degree of stiffness to the lathe for greater accuracy, I'm sold. I need to build a stand for the atlas and I was thinking I like a lot of the things this gent mentions with a "beam" mounting: Or perhaps it's only "flexible" when compared to a 3000 lb dedicated shop type lathe? Is it the ways that are "flexible"? or is it in the cross slide? the head? I say flexibility since that seems to be the major thing that is usually pointed out. Now, I still haven't picked mine up (10X36 or maybe a 42, remains to be seen) but I would like to address any "flexibility" items while I'm cleaning, restoring and setting it up. Web site will assume no responsibilities for damages or injuries resulting fromĢ021 (formerly owwm.Generally, I find the Atlas lathes are put down by professionals and sort "damned with faint praise" by hobbyists (IE:it's good enough). Good judgment and to safely operate old machinery. Themselves may not meet modern standards.

#Atlas lathe machine manuals#

Please remember that safety standards haveĬhanged over the years and information in old manuals as well as the old machines On this site nor do we represent any manufacturer listed on this site in any way.Ĭatalogs, manuals and any other literature that is available on this site is madeĪvailable for a historical record only.

does not provide support or parts for any machines Our purpose is to provide information about vintage machinery that is generallyĭifficult to locate.

#Atlas lathe machine professional#

PLEASE NOTE: was founded as a public service toĪmateur and professional woodworkers who enjoy using and/or restoring vintage machinery.

#Atlas lathe machine manual#

THE AXLES WERE TO MOUNT A HYDRAULIC TOE BRAKE SYSTEM TO REPLACE THE HEEL MANUAL BRAKES. I HAVE MADE AXLES FOR MY KR2 AIRPLANE AND HAD MUCH FUN IN IT.

#Atlas lathe machine how to#

I WISH DAD WAS HERE TO TEACH IS 84 YEAR OLD SON HOW TO REALLY USE IT. I HAVE NOW MOVED TO TEXAS AND HERE THE DRY CLIMATE AND A BIG SHOP I NOW HAVE WILL LET ME RESTORE THIS EXCELLENT MACHINE.ĭAD HAD LOTS OF TOOLS AND PARTS AND WAS METICULOUS IN WHAT HE DID. EVERYTHING RUSTS, THERE NO MATTER IF YOU KEEP IT OILED. I BUILD A SHOP AT THE HOME IN MISSISSIPPI AND THEN IN 2011 I MOVED TO FLORIDA TO LIVE ON THE OCEAN.

HE PASSED AWAY IN THE EARLY 1980'S AND MOTHER GAVE IT TO ME. MY FATHER BOUGHT THIS LATHE IN FREDERICKSBURG, TEXAS ABOUT 1966.

0 kommentar(er)

0 kommentar(er)